Saw for cutting of rubber profiles

TCM - THOMAS CONSTRUCTIONS MÉCANIQUES, manufacturer of special machinery, develops, designs and manufactures machines to meet your needs.

This sawing and cutting machine for rubber profiles is mainly designed for companies involved in the extrusion, cutting, machining and/or moulding of gaskets, as well as for manufacturers of custom-made shaped rubber parts, assemblies and sub-assemblies.

The saw cuts the profiles into sections from 10mm up to 10m in length, regardless of their section, up to 200 x 200mm.

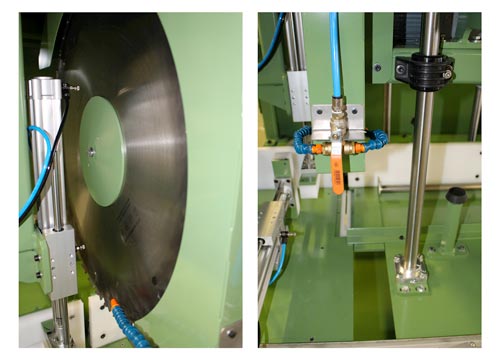

The gouge blade, specifically for cutting rubber material, features 3 cutting edges.

A lubrication system can also be supplied as an option.

The saw has a rotation speed of 3,200 rpm.

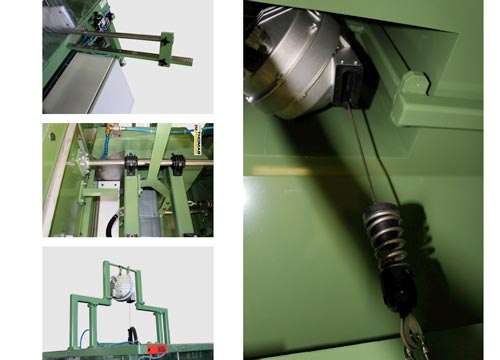

The saw is equipped with a balancer as standard, which takes the load of the blade support and the motor to ensure optimised ease-of-use, the well-being of the operator and the overall ergonomics of the unit.

The blade support guidance system has been specially designed to significantly reduce friction and thus the effort required; slight pressure is applied by hand to raise and lower the blade during cutting, which also limits the risk of muscular-skeletal injuries.

The profiles to be cut are pneumatically clamped in place.

This clamping system is integrated into the saw, so the operator does not have to enter the machine enclosure; they can operate it safely from the outside while ensuring a high level of cutting quality.

The blade actually remains at nominal speed during the different phases of execution (feeding and positioning of the profile, clamping, cutting, removal of the cuttings), guaranteeing better production efficiency.

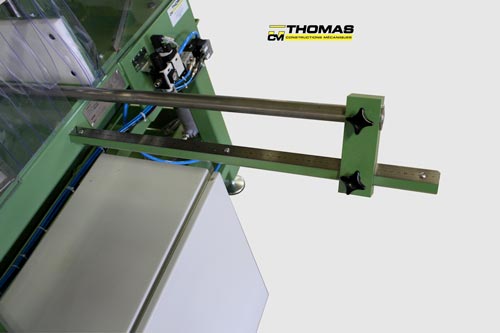

An adjustable stop system, positioned outside the saw enclosure, is used to adjust the cutting length easily and safely.

Via the hatch, the operator can safely remove parts of ≤ 600 mm in length and put them in a collection bin located under the machine.

For cuttings of > 600 mm, a conveyor can be installed at the saw exit to recover them.

The collection bin is mounted on wheels to facilitate the transportation of the cut pieces and cleaning.

A retention tank is used to easily recover waste (offcuts and chips) and the lubrication liquid.

There is a grille to filter out heavy waste and a strainer to filter out fine particles.

All the retractable parts (doors, collection tank, etc.) are equipped with magnetic locks that prevent the blade from starting if these parts are missing or incorrectly positioned.

The unit complies with the current European safety regulations in force.