Business sectors

and examples

of projects

TCM Business sectors and areas of strategic development

As our projects are almost always subject to confidentiality rules, presenting some of our most important and most innovative projects is a little complicated.

Nonetheless, below we have provided a few examples of our customers and achievements in order to demonstrate the broad scope of the projects that we work on daily.

Insect breeding and feeding

TCM - THOMAS CONSTRUCTIONS MECANIQUES, developer of innovations, designs and produces industrial insect breeding, feeding and processing facilities for the agri-food industry. This custom-made automated and semi-automated equipment is designed for insect breeding and processing to produce insect proteins for animal and plant nutrition.

These modular units are ideally suited to insect breeding in vertical farms, in fully automated or semi-automated industrial facilities specialising in the production and manufacture of insect proteins:

- Vertical farm management system

- Feeding system, feed preparation and distribution system

- Insect/substrate sorting and separating system

- Insect feed processing plant (sterilisation, separation, etc.)

- System for treatment, recycling and processing of waste/by-products/frass/insect fertiliser

- Conveyor and transfer system for by-products

- Cleaning system

- Packaging and wrapping unit

- Feeding of different components

- Dosing of different components

- Preparation of the feed mixture

- Mixing

- Stabilisation of the substrate (homogeneity & phase shift)

- Temperature control

- Sampling/quality control

- Automated Clean in Place (CIP system) with temperature control

- Rinsing

- Distribution and volumetric dosing of substrate

- Wastewater filtration

- Recovery of surplus for further processing

Agri-food industry

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the agri-food industry is one of the four historical sectors of activity that have driven our growth. Among other organisations, we work with the main industrial cheese dairies in the region, which have shown us unfailing loyalty.

- the use and machining of stainless steel

- dosing systems for viscous foodstuffs

- food elevators

- conveyor systems

- stacking systems

- food elevators

- process piping

- robotic units

- special packaging and wrapping machines

- dosing workstations

- cleaning systems

- control cabinets with PLC

- maintenance of equipment and infrastructure

- repairs

- technical upgrading of existing equipment

- Safety compliance of existing equipment

- knitting machines for agri-food nets

- stretching and cutting machine for plastic film

- pastry dough machine

- packaging press for agri-food nets

- cheese spraying and refrigeration line

- cheese packing line and cheese stack elevator

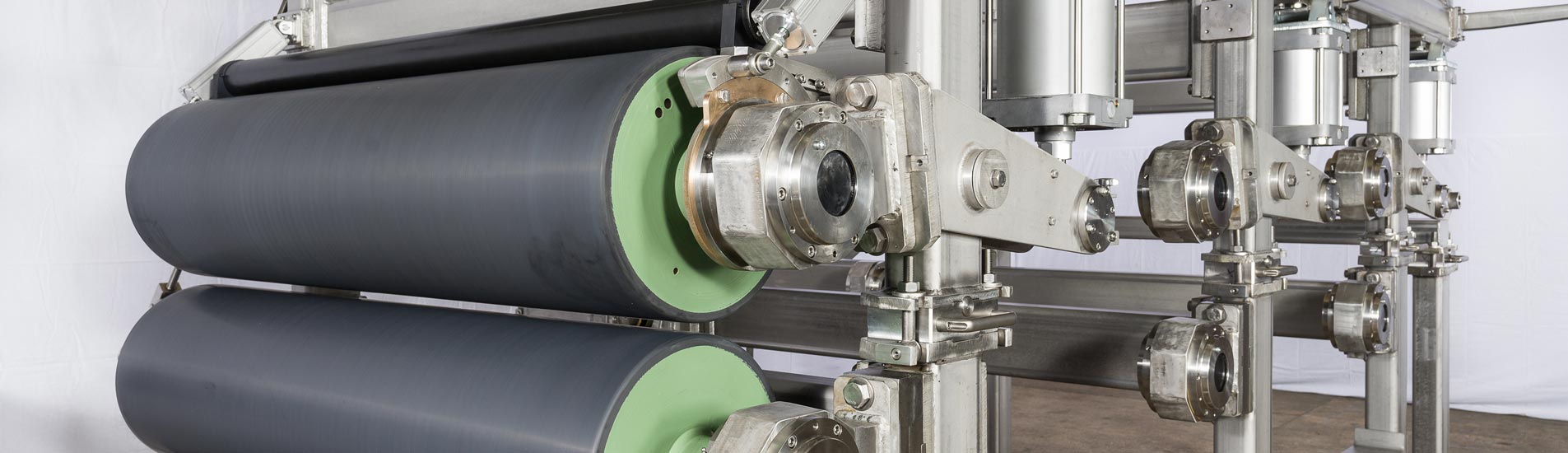

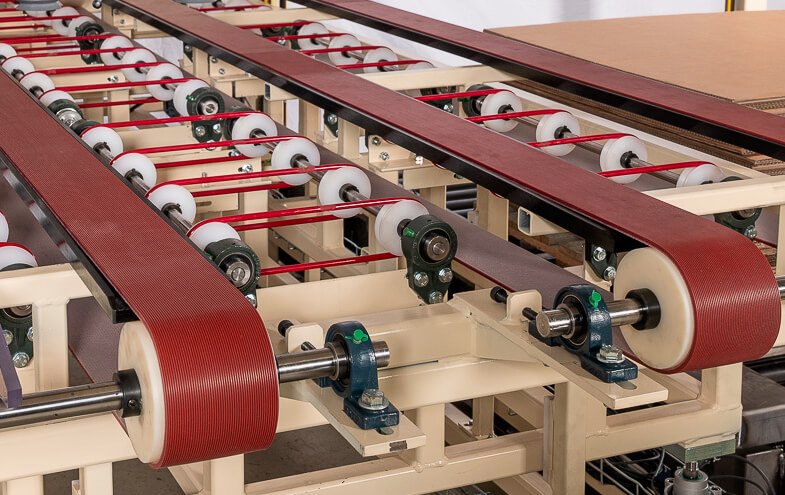

Paper industry

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the paper industry is also one of the four historical sectors of activity that have driven our growth. We work closely with the main paper mills in the region which, despite the increasing global nature of their business, have still shown us unfailing loyalty.

- the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity

- conveyor systems and roller elevators

- conveyor systems

- roller elevators

- special packaging and wrapping machines

- the upgrading of existing paper mills to reduce set-up and adjustment times and increase productivity

- maintenance of equipment and infrastructure

- repairs

- technical upgrading of existing equipment

- Safety compliance of existing equipment

- container tipper

- roller elevator

- fiberiser

- barrel washer

- conveyor and transfer system for finished or semi-finished products

Wood processing industry

As with the paper industry, because of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges woodlands, the wood processing industry is the third key industrial sector that has driven our growth. Among many other customers, we work with the leading manufacturers of MDF panels and reels for the storage and transport of electrical cables.

- the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity

- conveyor systems

- wood cutting systems (sawing)

- wood sanding systems

- wood nailing and assembly systems

- conveyor systems

- wood cutting systems (sawing)

- wood sanding systems

- wood nailing and assembly systems

- robotic units

- maintenance of equipment and infrastructure

- repairs

- technical upgrading of existing equipment

- Safety compliance of existing equipment

- upgrading of an existing MDF sawing and sanding production plant to reduce wear on consumables and make operational efficiency gains

- crimping machine for ferrules on cable reels

- wood-cutting machine for small farms

- cutting and stacking system

- wood-cutting machine for small farms

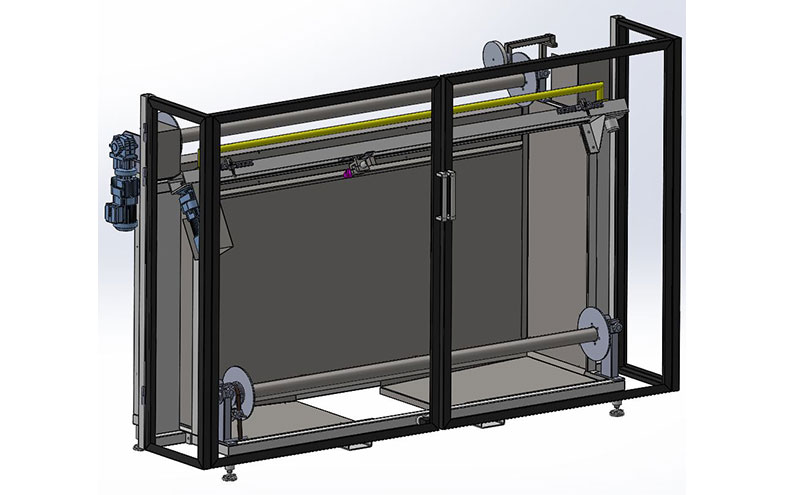

Textile industry

The textile industry is the fourth key industrial sector that has driven our growth because of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges.

- special packaging, wrapping and labelling machines

- ergonomic workstations

- maintenance of equipment and infrastructure

- repairs

- technical upgrading of existing equipment

- Safety compliance of existing equipment

- towel packing and labelling unit

- ergonomic handling workstation

Metallurgy, Steel industry

- conveyor systems

- winding systems

- winding system for drawing mill

- steel wire winder series

- feed modules for cylindrical cutting blow torch

Automotive industry

- conveyor systems

- assembly lines

- robotic units

- screwing

- welding

- Poka-Yoke

- vision

- Pick and Place

- roll-forming machine

- conveyor system with elevator

- assembly lines for plastic and metal components

- ergonomic workstation on assembly line

- unit for recovery, transfer and removal of springs on assembly line

Non-destructive testing

- integration of non-destructive testing equipment in an industrial environment

- dimensional checks

- tomography

- 3D vision

- X-ray

Miscellaneous

- high-capacity transhipper

- wire expansion machine for sleeves

- heat treatment furnace

- gripper

Areas of strategic development

We are actively working on the following areas of strategic development:

Business sectors :

- environment and renewable energy

- peripheral equipment for the transport of lightweight consumer goods (≤ 10 kg) by autonomous drones via aerial highways

- peripheral technological equipment for self-driving land vehicles

- development and integration of specialist digital solutions for automated production processes