Capitalise on

our capacity

for innovation

Think out of the box!

What if you tried a break from the norm?

When you entrust your project to TCM – THOMAS CONSTRUCTIONS MECANIQUES, you’re guaranteed an innovative solution:

- Do you have a patented product or process that needs to be industrialised?

- Equipment you want to monitor remotely?

- A production process that could be simplified or streamlined using voice recognition technology?

- Image recognition technology to be integrated?

- A production cost that could be minimised through digitisation?

- And many other projects that need to be realised...

With our three key pillars of innovation, we approach your technical problem from a global perspective by thinking outside the box and creating innovative solutions.

Technology watch and R&D

Our constant technological watch (materials, processes, robotics, artificial intelligence, etc.) focuses namely on the commercial availability of the most recent and varied techniques.

In this way, we overcome each problem by adopting a broader approach and by integrating these techniques into our special machinery.

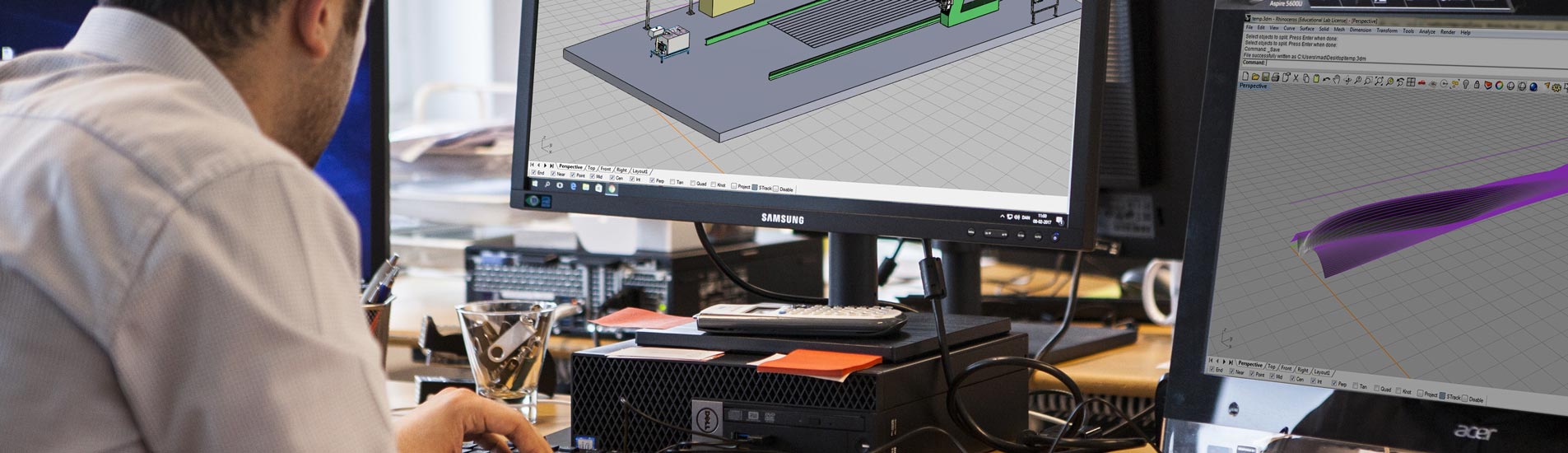

Design and engineering office

Our design office has gained over 75 years’ experience in developing exclusive technical solutions to solve unique problems.

Each problem is the subject of a specific analysis and a global strategic planning process taking into account feasibility, optimisation and profitability.

Digitisation

Control, monitoring, imaging, voice recognition, augmented reality, localisation and security: digitisation is increasingly being incorporated into the design of special machines.

It meets specific technical needs while being free from the usual constraints of geographical location and physical presence. We provide you with proven solutions that combine reliability and simplicity.

From innovation to reality

At each stage of research and development throughout your project, we hold strategic planning meetings with the design office and the manufacturing workshops, so that we can fully capitalise on our internal theoretical and practical skills, as well as having co-engineering discussions with your teams.

The close collaboration between our development and manufacturing teams enables us to combine theoretical creativity and best practice.. Any technical solution undergoes a practical feasibility and optimisation analysis upstream in

the manufacturing phases.

The various solutions studied are reviewed again, with the final decision being made according to the solution that offers the best balance between technicality, productivity, efficiency and cost.