Integrated,

highly-experienced

design office

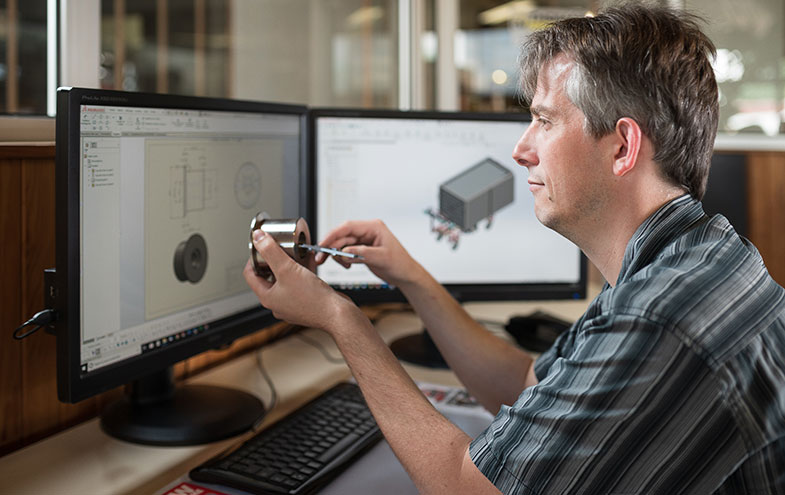

Experienced designers who are highly involved in the manufacturing process

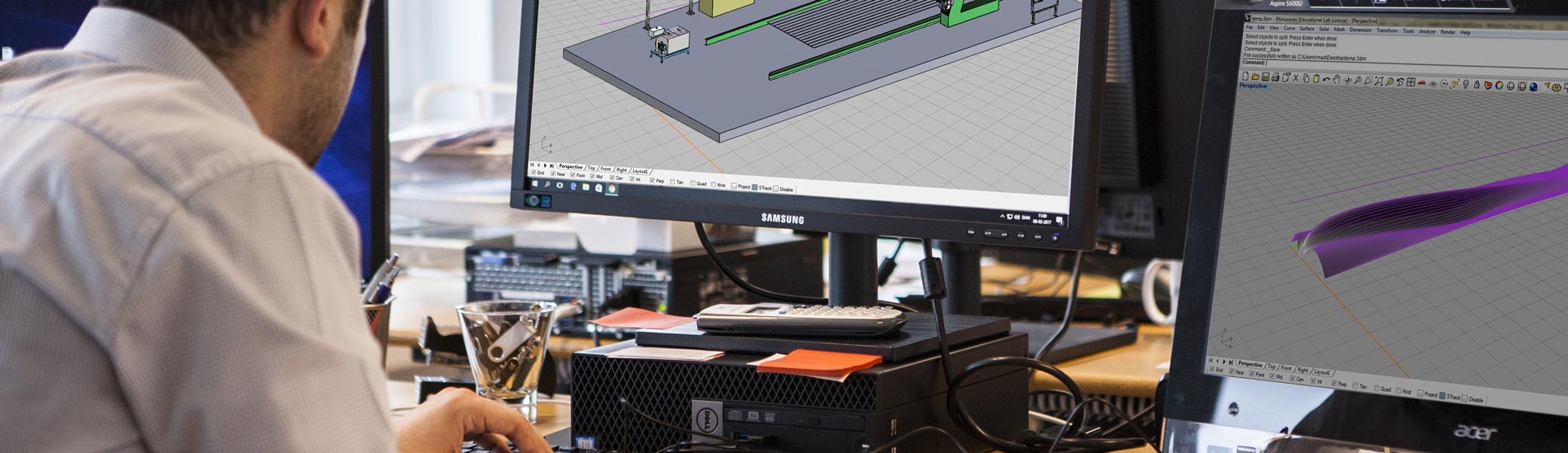

By adopting an approach which combines realism with modernity, our design office focuses on developing solutions based on production engineering in full compliance with your quality, production, and budgetary requirements.

A multidisciplinary methodology

At each stage of research and development throughout your project, we hold strategic planning meetings with the design office and the manufacturing workshops, so that we can fully capitalise on our internal theoretical and practical skills, as well as having co-engineering discussions with your teams.

The close collaboration between our development and manufacturing teams enables us to combine theoretical creativity and best practice..

All technical solutions undergo a practical feasibility and optimisation analysis upstream in the manufacturing phases.

The various solutions studied are reviewed again, with the final decision being made according to the solution that offers the best balance between technicality, productivity, efficiency and cost.

Theoretical approach

Each study is subject to an exhaustive analysis using computer-aided design and drafting (CADD). Structural strength is calculated based on finite elements. The production cycles and productivity of facilities are based on iterative optimisation studies through reverse engineering.

Practical validation

Solutions requiring pre-validation phases are tested in our workshops.

We don’t need to call on intermediaries or subcontractors, we have the required expertise in the trades and the value chain needed to install and monitor your equipment. With this extensive know-how, we provide guaranteed effective solutions in compliance with your needs.

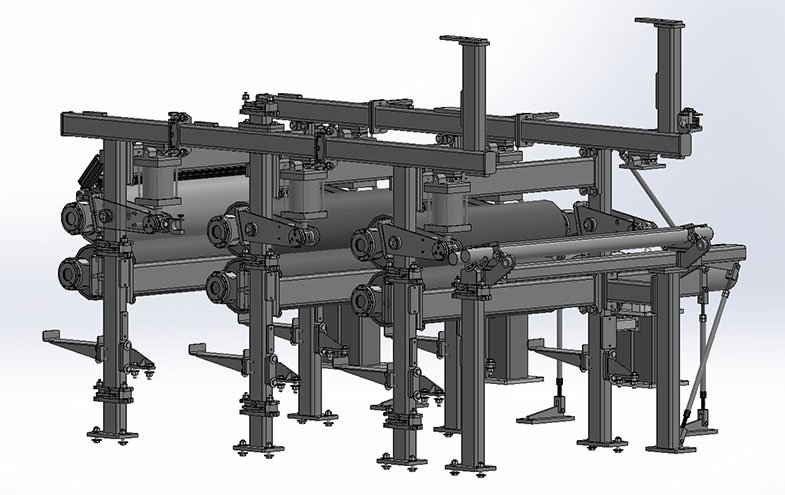

Our diversified machine fleet (machining, welding, cutting, forming) and our assembly and testing facilities (mechanics, hydraulics, pneumatics, electrics, automation) facilitate and speed up the manufacturing process for the prototypes and test modules required for pre-validation and pre-qualification.

Identification of your constraints

Environmental and functional constraints (safety, cleanliness, hygiene, accessibility, ageing, etc.) are duly listed and taken into account in the design constraints.

Design and engineering office

Our teams of engineers and technicians conduct all the necessary design and engineering studies for your projects.

Based on your needs analysis or specifications, our teams produce the mechanical and electrical working drawings, other manufacturing documents, automation software, etc.

They perform development testing and commissioning operations on site. Our technical solutions are developed according to your requirements while prioritising a custom-made product that combines performance and reliability.

A turnkey service

With our global approach, multidisciplinary teams and extensive expertise of manufacturing industries, we provide robust, reliable and durable turnkey solutions.