Design & production

of special machinery

We have been designing, producing, maintaining and upgrading special machinery for over 75 years!

For over 75 years, TCM - THOMAS CONSTRUCTIONS MECANIQUES has been a major player in the design and manufacture of special machinery for all sectors of activity and for multiple uses.

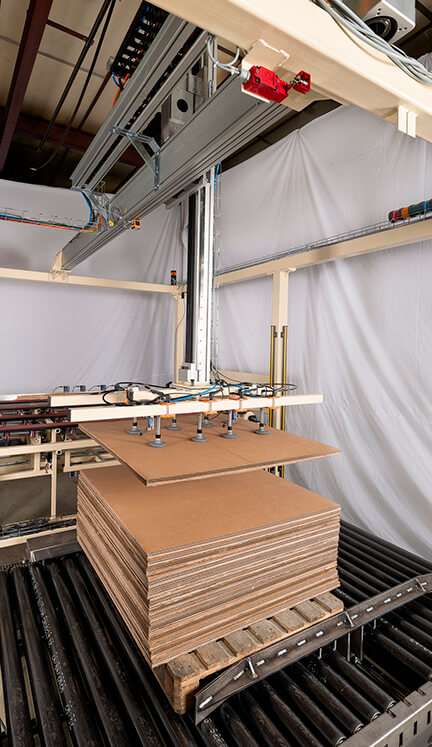

- Handling, lifting and conveyor systems

- Packaging, wrapping and labelling lines

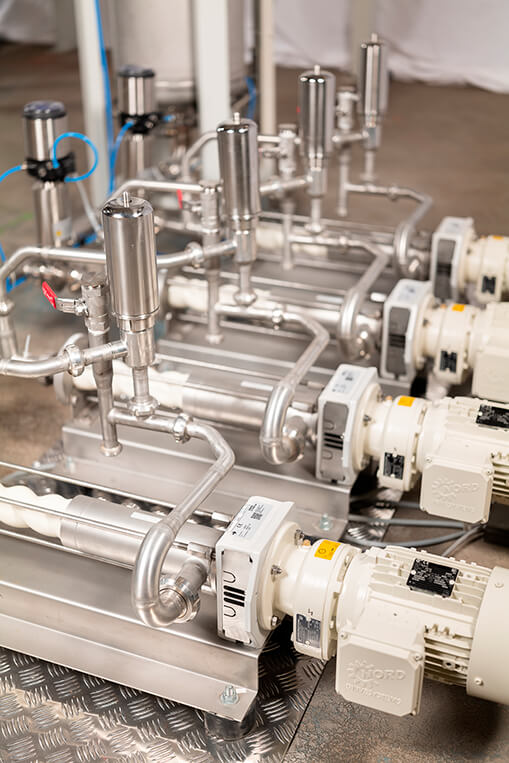

- Dosing systems

- Automated or semi-automated assembly lines

- Semi-automated manufacturing workstations

- Automated handling and feeding stations

- Design and manufacture of ergonomic workstations

- Design, integration and operation of digital solutions to monitor and optimise production and maintenance processes

- Test and control benches

- Integration of robots, robotic units and cobotics solutions

- Design and roll-out of augmented reality technical support solutions

- Design and roll-out of remote monitoring solutions

- Design and integration of solutions for:

- vision and industrial imaging

- marking

- automatic screwing

- crimping and riveting

- mechanical and electrical control

- integration of vibrating bowls

- modernisation and technical upgrading of existing equipment

Your project is central to our concerns.

Each of your projects will be managed by a single, highly-qualified project manager. They will be your special contact and will manage all the stages of your project, from the technical and financial proposal to the acceptance of your equipment.

With our many years of experience in the industry, we are well-placed to understand the specific characteristics of your business and analyse them, anticipate problems and assess the level of risk.

At each stage of research and development, your project is the central focus of strategic planning meetings between our Design Office and manufacturing workshops, in order to capitalise on both our technical expertise and practical know-how, all while having valuable co-engineering discussions with your teams.

Bright minds

and deft hands

The close collaboration between our development and manufacturing teams enables us to combine technical precision, creativity and best practice.

Any technical solution undergoes a practical feasibility and optimisation analysis upstream in the manufacturing phases.

The various solutions studied are reviewed systematically. The final decision is made according to the solution that offers the best balance between technicality, productivity, efficiency and cost.

The size of our organisation and our multi-disciplinary expertise means we can provide a flexible, seamless and proactive response to any modification.

Solutions requiring pre-validation phases are tested in our workshops.

With our comprehensive expertise in a range of trades and control of the value chain, there’s no need for intermediaries or subcontractors, guaranteeing the efficiency of the chosen solutions and their compliance with your needs.

Fail-safe project management

We manage your project with diligence and flexibility:- Analysis of your requirements

- Drafting of a technical and financial proposal

- Approval of the project

- Preparation of a detailed implementation schedule

- Manufacture of the installation

- Pre-acceptance at our premises

- Customer training

- Installation and commissioning at the customer’s site

- Final acceptance

- After-sales support

We take on every project with the same commitment and engagement, whatever the size or degree of complexity.

We manage with careful attention and discipline:

- the timeliness of responses

- production and delivery deadlines

- validation and acceptance phases

- budget control