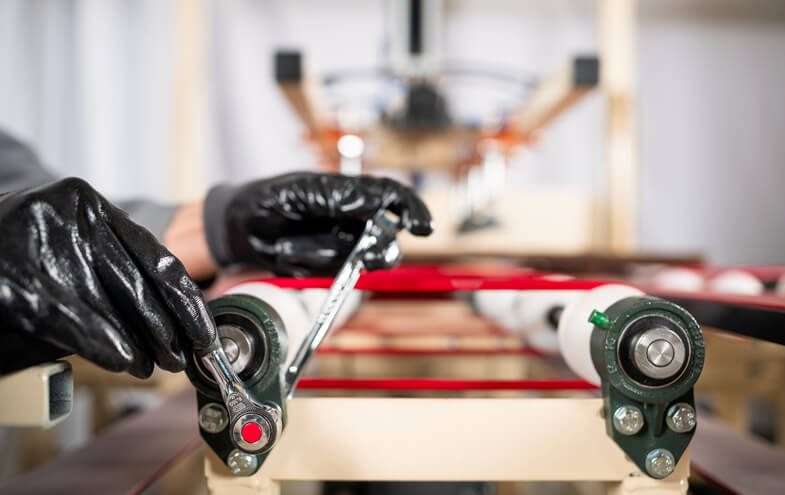

Special machinery

Quality control

Special machinery: quality control, commissioning and after-sales service

Quality does not mean over-quality, at TCM – THOMAS CONSTRUCTIONS MECANIQUES, quality is an ongoing commitment to your satisfaction: whatever your project, we develop the technological solution best suited to your product and your customers’ expectations, according to your internal resources, environment and budget. Your satisfaction is our sole objective.

Quality control at every stage

The intrinsic quality of the various components, sub-assemblies and software is checked at each stage of design and manufacturing.During the pre-validation phases, performance, durability, and efficiency goals are meticulously assessed and cross-checked with the obligations defined in the specifications.

These efficiency targets are cross-referenced and verified with our customer upon commissioning of the equipment, following the implementation of a duly developed validation protocol.

Commissioning

The assembly and commissioning phases on site are carefully planned in terms of time, human resources and technical means so as to avoid any disruption to your production flows.

These preparations are organised in close collaboration with your production and maintenance teams.

Skills transfer

We have qualified employees who are fully accustomed to working on site with customers, whether independently or with teams working in other trades.

Our team have all the necessary qualifications and training to install high-quality facilities in strict compliance with safety regulations.

Throughout the commissioning phase, we will train your operators to use the equipment.

We also train your maintenance teams in equipment troubleshooting.

After-sales service

We have an after-sales team at your disposal which can diagnose and troubleshoot any electrical, IT or mechanical problem in the shortest possible timeframe.Depending on the case, we can also offer to install remote control systems that operate via telephone or internet connection, such as Teamviewer, VNC or Cisco VPN Client.

As a result, we can perform maintenance operations very quickly on equipment without the need for an on-site visit, regardless of the distance.