Oil machine for production of breaded products

TCM - THOMAS CONSTRUCTIONS MÉCANIQUES, specialist in agri-food machinery, designs and manufactures innovative machines for specific processes.

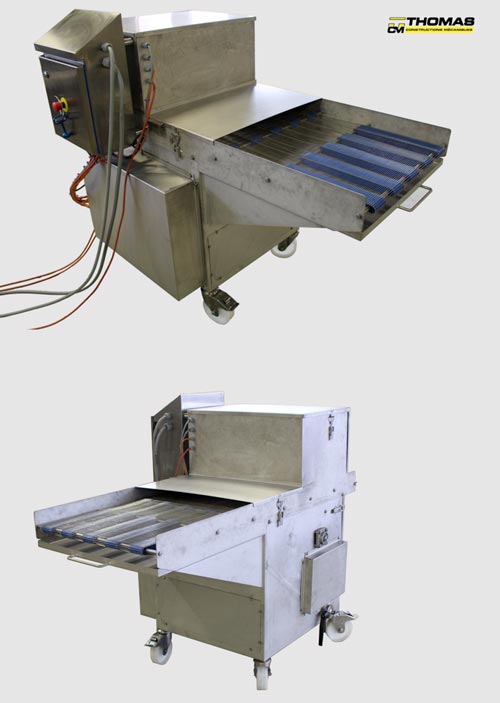

This machine is used to spray hot oil on breaded food products.

It is made entirely of stainless steel and strictly complies with current food standards for industrial use.

Mounted on wheels, the oiler is removable; this function makes it easier to clean the area around the machine.

Moreover, this unit can be easily integrated into different manufacturing lines according to your production needs.

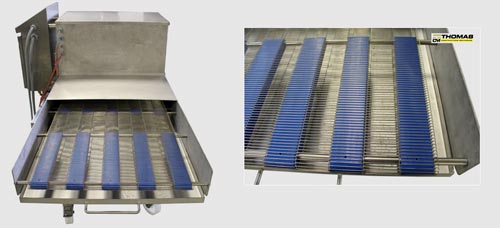

The integrated conveyor consists of a stainless steel chain which drains the products at the end of the process.

The guides are made of blue HDPE and comply with food standards both in terms of contact with foodstuffs and quality; if the guides become worn, their blue colour makes it easy to detect the presence of particles that could come into contact with the products.

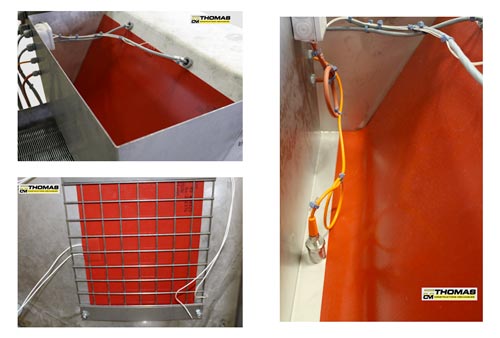

Heated mats are positioned all around the oil tank, along with a temperature sensor to heat and maintain the sprayed oil at the optimal temperature.

These mats are positioned outside of the tank and are not in direct contact with the oil, unlike immersed-resistance heating systems.

Therefore, the integrity of the oil is preserved throughout its useful life.

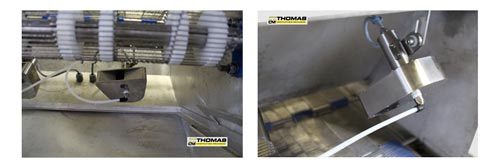

Specially-sized and strategically-positioned sprayers spray the oil onto the top and bottom of products, so that the entire surface of products are sprayed with oil.

The system features a PLC which controls and regulates the flow rate of the oil pumps, sprayers and speed controller to ensure the optimal amount of oil per square centimetre is applied to products.

To make it easier to clean the machine, the protective covers in the spraying area can easily be removed without tools using the quick-release fasteners.

There are also built-in safety sensors to prevent the oiling machine from starting up if the protective covers are not in place.

In addition, removable retention tanks are positioned under the conveyor chains to collect and evacuate any breadcrumb and oil residue.

A fine-mesh screen that can be removed without using tools collects the breadcrumbs: this prevents the oil from being contaminated and significantly reduces the risk of clogging in the oil circulation circuit.

The used oil is easily drained away using a valve with a safety catch.

The electrical cabinets, with one built into the machine and the other remote, are made of stainless steel and are perfectly suited to the food industry.