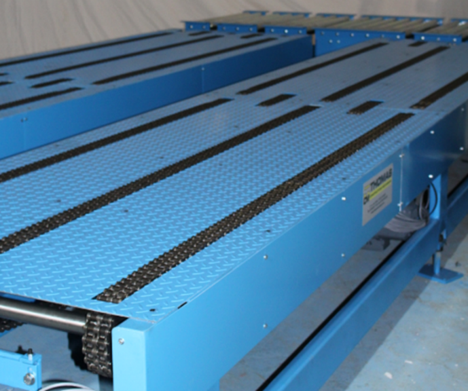

High-capacity automatic conveyor system for heavy loads

A European multinational company, today, our customer is the largest manufacturer of covering and waterproofing solutions for flat and pitched roofs.

With the aim of optimising the production capacity of one of its manufacturing sites, the company commissioned TCM - THOMAS CONSTRUCTIONS MECANIQUES to develop a high-capacity automated conveyor system for heavy loads.

With the constraints of an extremely short production downtime and the need for operational production to start urgently, this unit was developed, designed, manufactured and commissioned in record time.

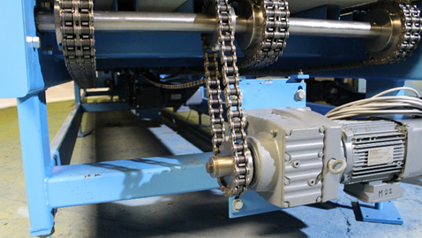

This fully automatic conveyor system is controlled by a central PLC. It is a high-capacity conveyor which transports pallets of over one ton to the end of the packaging line. It is composed of chain conveyors, roller conveyors and a bidirectional transfer station. The system is designed to withstand extreme operating conditions (high ambient temperature, very dusty environment, high ambient humidity).

Developed according to a production philosophy in line with our customer’s strategic productivity and profitability targets, this conveyor system is a unit that can be integrated into an existing and complex manufacturing line, optimising productivity and the overall efficiency of the manufacturing facility at lower cost.

In late 2019, a wide range of design, development and manufacturing work was carried out by TCM - THOMAS CONSTRUCTIONS MECANIQUES - see the following articles for more information:

- “Metton milling machine for the agri-food industry”

- “Continuous height control workstation with 4.0 digital monitoring and reporting via an online platform”

- “Tri-material synthetic tube cutting unit for the cable sector and the energy and communication systems industry”