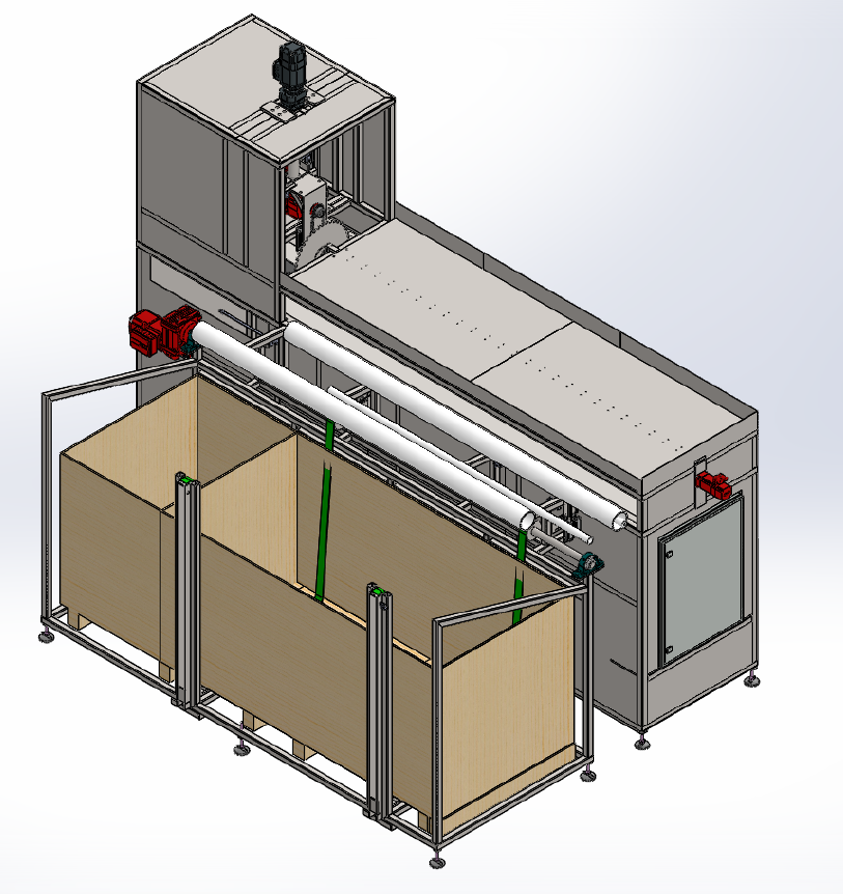

Tri-material synthetic tube cutting unit

The latest technological and industrial news at TCM - THOMAS CONSTRUCTIONS MECANIQUES attracted plenty of media buzz at the end of 2019.

TCM - THOMAS CONSTRUCTIONS MECANIQUES was instructed to design a cutting unit for tri-material synthetic tubes by a major international player in the cable and energy and communication systems industry.

This fully automated unit is controlled by a central PLC operated via a digital screen; the raw synthetic tubes are fed into a feed hopper in bulk.

The cutting operation, automatically adjusted and according to the finished product’s characteristics, is performed within a tolerance of perpendicularity to the tube axis of ± 2%. The finished products are completely free of internal and external burrs,

chips and all traces of lubricant and dirt. The noise produced by the machine is limited to 71 decibels.

The tube offcuts are evacuated by grouping them together in a dedicated hopper. Upon exiting the unit, the finished product is automatically transported to a temporary storage area and then transferred to a robotic unit for further processing.

TCM - THOMAS CONSTRUCTIONS MECANIQUES oversaw the entire industrialisation process for the unit, incorporating all the design, manufacturing and development phases, with these last two phases scheduled for December 2019.

In late 2019, a wide range of design, development and manufacturing work was carried out by TCM - THOMAS CONSTRUCTIONS MECANIQUES - see the following articles for more information: